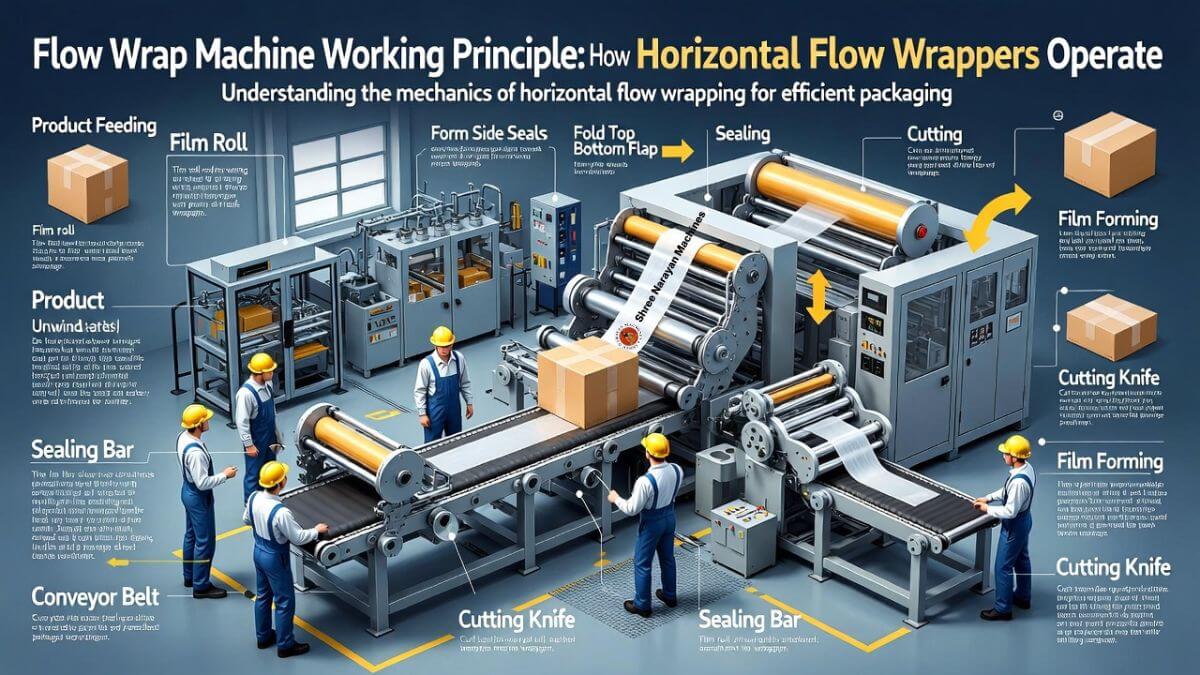

In modern packaging, efficiency and hygiene are non‑negotiable. Among the most versatile solutions is the Flow Wrap Machine, also known as a horizontal flow wrapper. Widely used in food, pharmaceuticals, and FMCG, this machine wraps products in a continuous film, producing secure pillow‑style packs. Understanding the working principle of a flow wrap machine helps manufacturers evaluate performance, optimize ROI, and ensure consistent packaging quality.

What Is a Flow Wrap Machine?

A flow wrap machine automates the process of enclosing products in flexible film. It forms a tube around the product, seals it longitudinally, and then applies transverse seals to create individual packs. This continuous motion makes it ideal for high‑speed packaging of biscuits, chocolates, soaps, syringes, and hardware items.

Step‑by‑Step Working Principle

The operation of a horizontal flow wrapper can be broken down into four synchronized stages:

1. Film Feeding and Tube Formation

- A roll of packaging film is mounted on the machine.

- The film is drawn under constant tension and guided around a forming box.

- This creates a continuous tube around the conveyor‑fed product.

2. Longitudinal Sealing

- The film edges are sealed lengthwise using heat or ultrasonic sealing.

- This ensures the product is enclosed in a tight, hygienic film tube.

3. Product Indexing and Positioning

- Servo motors synchronize product feed with film movement.

- Each product is precisely positioned inside the film tube to avoid misalignment.

4. Transverse Sealing and Cutting

- Rotary sealing jaws apply cross seals at regular intervals.

- The sealed tube is cut into individual pillow packs, ready for retail presentation.

Key Components in the Working Principle

- Film roll & tension control system – ensures smooth feeding.

- Forming box – shapes the film into a tube.

- Longitudinal sealing unit – creates continuous seals.

- Product conveyor – indexes products accurately.

- Transverse sealing jaws – apply end seals and cut packs.

- PLC & HMI controls – allow recipe storage and quick changeovers.

Advantages of Flow Wrap Machine Working Principle

- Continuous operation enables high speeds (40–250 packs/min).

- Reduced film waste through precise tension control.

- Consistent sealing quality improves shelf life and brand image.

- Versatility across multiple product sizes and film types.

- Integration with upstream feeders and downstream conveyors.

Applications

- Food packaging: Biscuits, chocolates, bakery items.

- Pharma packaging: Syringes, medical devices, blister packs.

- FMCG: Soaps, stationery, hardware items.

Also Read: How Does a Flow Wrap Machine Work – Step-by-Step Packaging Guide

Conclusion

The working principle of a flow wrap machine is a synchronized process of film feeding, sealing, and cutting that delivers speed, hygiene, and consistency. By understanding how these machines operate, manufacturers can optimize production, reduce costs, and ensure compliance with industry standards.