The demand for biodegradable sanitary pads is rising rapidly as consumers, NGOs, and governments push for eco‑friendly menstrual hygiene products. Traditional pads often contain plastics and non‑biodegradable materials that take centuries to decompose, creating environmental challenges. A biodegradable sanitary pads making machine offers a sustainable solution by enabling manufacturers to produce pads using natural fibers, compostable films, and plant‑based absorbents.

Why Biodegradable Sanitary Pads?

- Environmental impact: Conventional pads generate tons of non‑biodegradable waste annually.

- Consumer preference: Increasing awareness of eco‑friendly menstrual hygiene drives demand.

- Government initiatives: Policies and subsidies encourage sustainable manufacturing.

- Market opportunity: Startups and NGOs can tap into a growing niche with high social impact.

Features of a Biodegradable Sanitary Pads Making Machine

- Eco‑friendly raw material compatibility

- Cotton, bamboo fiber, banana fiber, and biodegradable backsheet films.

- Automated production line

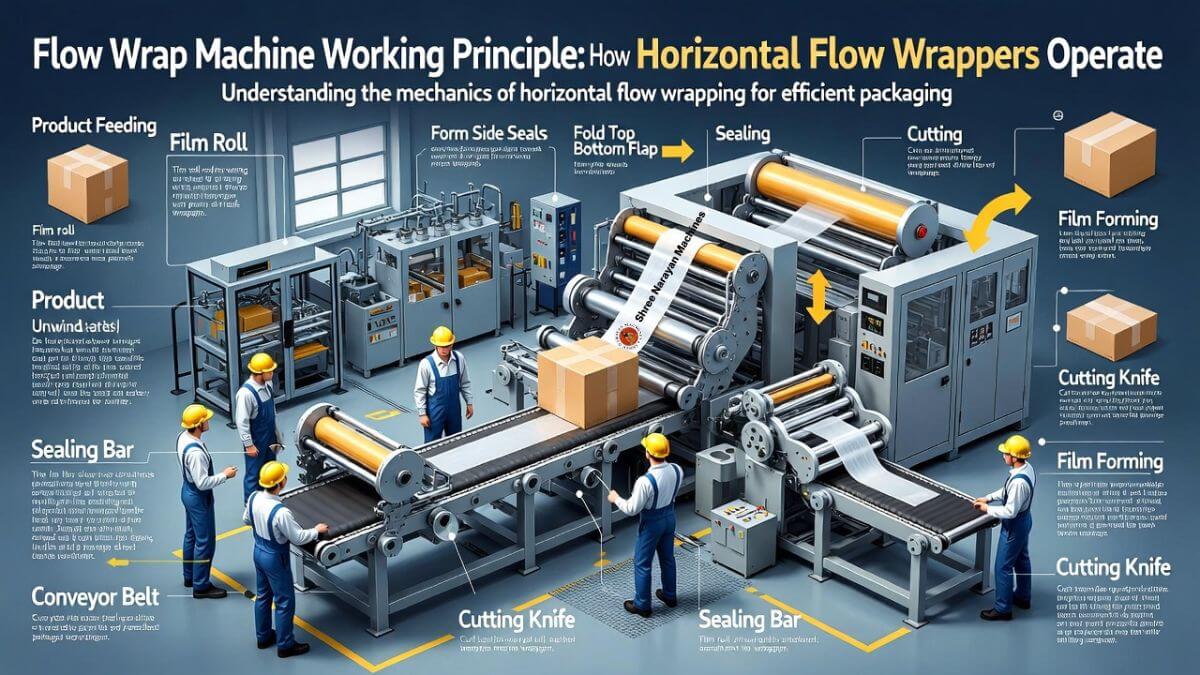

- PLC control, servo motors, and ultrasonic sealing for precision.

- Flexible pad sizes

- Regular, overnight, and winged pads with customizable absorbency.

- Hygienic construction

- Stainless steel surfaces, easy‑clean design, and dust‑free operation.

- Optional modules

- Hot‑melt adhesive applicators, wing folding units, and automatic stacking.

ROI and Business Impact

Investing in a biodegradable sanitary pad machine is not just about profits—it’s about sustainability and social responsibility.

- CAPEX: Initial investment includes machine cost, installation, and training.

- Savings: Reduced environmental compliance costs and eligibility for subsidies.

- Revenue growth: Premium pricing for eco‑friendly pads and access to NGO/government tenders.

- Payback period: Typically 2–3 years, depending on production scale and market penetration.

Applications

- Startups & entrepreneurs: Launch eco‑friendly brands targeting urban and rural markets.

- NGOs & self‑help groups: Provide affordable biodegradable pads to communities.

- Large manufacturers: Diversify product lines with sustainable options.

Risks and Considerations

- Raw material sourcing: Ensure consistent supply of biodegradable fibers.

- Consumer education: Awareness campaigns may be needed to drive adoption.

- Maintenance costs: Eco‑friendly materials may require specialized handling.

Also Read: How Sanitary Pad Making Machines Improve Hygiene Standards?

Conclusion

A biodegradable sanitary pads making machine is more than a piece of equipment—it’s a gateway to sustainable innovation in menstrual hygiene. By combining automation, eco‑friendly materials, and hygienic design, manufacturers can meet consumer demand, reduce environmental impact, and achieve long‑term profitability.